HIGH PERFORMANCE MACHINING (HPM)

High Performance Machining is a technology that is particularly suitable when it comes to the removal of large volumes of material or the machining of difficult to cut materials. It helps to achieve the best possible results. The cutting tools that are primarily used are insert type milling heads, specific high performance end mills, drills, boring heads and special tooling.

SUNI is an expert in High Speed Machining and High Performance Machining. SUNI accompanies you in the democratization of these manufacturing processes, which has its place in every industrial company.

HIGH PERFORMANCE MACHINING APPLICABLE TO ALL TYPES OF MACHINERY

For example, on a vertical machining center with a gear limit of 6,000 rpm, it is possible to apply swarf reduction techniques and adjust the burrs over the whole length of the cutter. Performance can also be improved by integrating robot systems to relieve your workstations. This increases the productivity as it reduces the time cycle.

High Speed Machining refers to trochoidal toolpaths, with radial and axial depths of cut. Modern systems offer a large variety of possibilities to increase metal removal rates while improving tool life and parts quality.

These toolpath strategies work on all tooling machines. It is necessary to invest in cutting tools and tool holders as well as in an CAM system. The training aspect is essential; your operators, technicians and engineers will have to be trained to overcome this technological leap. High performance machining is comparable to driving a Formula 1 and requires progressive curve.

Era of connected manufacturing

What data is needed to be really efficient?

DATA AT THE SERVICE OF HIGH PERFORMANCE MACHINING

Machining 4.0 : the time of big data

Here are the buzzwords that appeal today : Smart Manufacturing, Industry 4.0, the Industrial Internet of Things or “IoT”. Soon, manufacturing will be highly linked to data. The data will tell you when to change tools, alert you before unexpected downtime occurs. Data analysis helps you to develop your process and track it in series from a quality point of view.

At the end of the day, data collection and analysis helps to achieve better quality and productivity. Industry 4.0 places efficiency at the heart of manufacturing processes.

Measure performance to improve it

The first step on the path of high performance machining is to understand the phenomena involved by the acquisition of physical measurements intrinsic to the process. SUNI has various modern investigative means : spindle which measures the cutting power, force acquisition platform, confocal optical microscope.

SUNI establishes a reference base, which makes it possible to understand the difficult points and technological constraints of the studied process, then to work to improve it. This method initiates a flexible processus, from the digital chain to manufacturing on your production line.

SUNI – PFT

15 years of HSM experience at your service

Our experience on high speed machining-hsm

High Speed Machining is part of the family of manufacturing processes that removes matter. The process remains very unique due to its performance (high removal rate) and the means to set it up.

- Its performance is far superior to that of traditional machining : spindle cutting speeds can rotate at over 60,000 rpm and feeds are 10 to 20 times faster than classical machining.

- To achieve such performance the associated environment must be set up with a range of high-level technological products ( Computer Assistance) and adapted training for employees.

- The organization of the workshop and sometimes the whole company, must be reviewed in order to allow an optimal performance of the H.S.M.

These three fundamental points require skills and related knowledge that are still often poorly understood as a whole.

I would like to switch to High Speed Machining

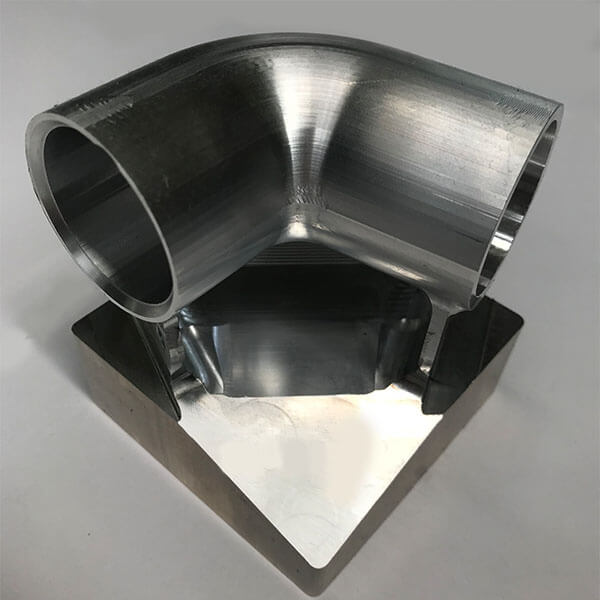

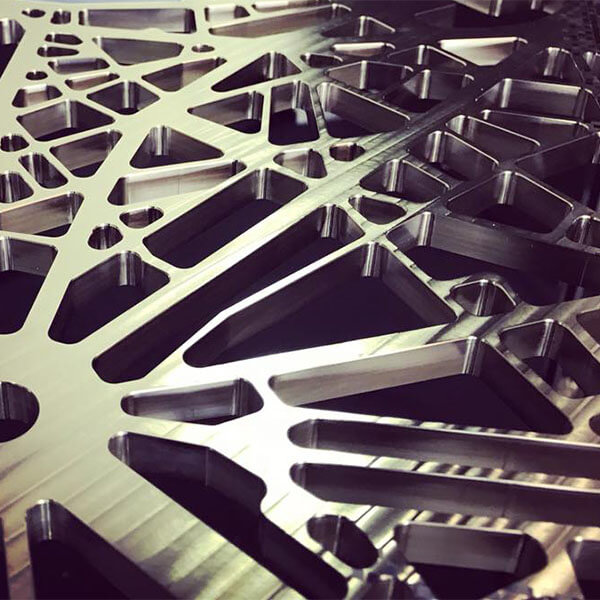

High Performance Machining in photos

Machining and drilling of composite materials

High Performance Machining for composite materials

HIGH PERFORMANCE MACHINING FOR COMPOSITE MATERIALS

Composites offer a variety of combinations. Between the different matrices, the different reinforcements, the loads and the reinforcement rates, each composite material is tested and studied for improving its usability (trimming, drilling, …).

SUNI has an adapted and optimized equipment to meet the specifics of such machining. SUNI also has the possibility of developing customized tools. Finally, microscopy solutions make it possible to detect and characterize any delaminating defects.

SUNI’s experience and methodological approach helps you to solve problems with composite. Different sectors, like aeronautics, already trust SUNI.

Would you like to implement high performance machining?

How to make this technological leap?

We can help you put in place best practices for H.S.M.

Still doubting about switching to H.S.M? Would you like to have access to R & D center with all the necessary ressources (testing facilities, investigative tools and customized cutting tool development)? You have already found it!

We propose for all your needs :

- three High-Speed Machining centers (3 and 5 axes). More precisely, various force measurements allow to detect tool wear, to compare conditions of cuts, and to capture key performance indicators results.

- modern ways of surveying : our acquisition platform is dedicated to the recovery of cutting forces along the three axes for the analysis of the key factors and determination of the optimal condition. The Alicona system is used to measure shapes and roughness.

- Our partnership since the beginning of 2008 with the E-Leclerc Company in Fougères, completes the material means with proven know-how in the design and manufacture of cutting tools, and is at your service for your High Performance Machining project.

I have a project that involves High Performance Machining

SUNI TECHNOLOGY PLATFORM

SUNI-PFT

Campus de Ker Lann

Avenue Robert Schuman

35170 BRUZ , France

+33 02 99 05 93 18

contact@suni-pft.fr

Find us

©All rights reserved SUNI 2018-2026

Design & Conception : Diginsol